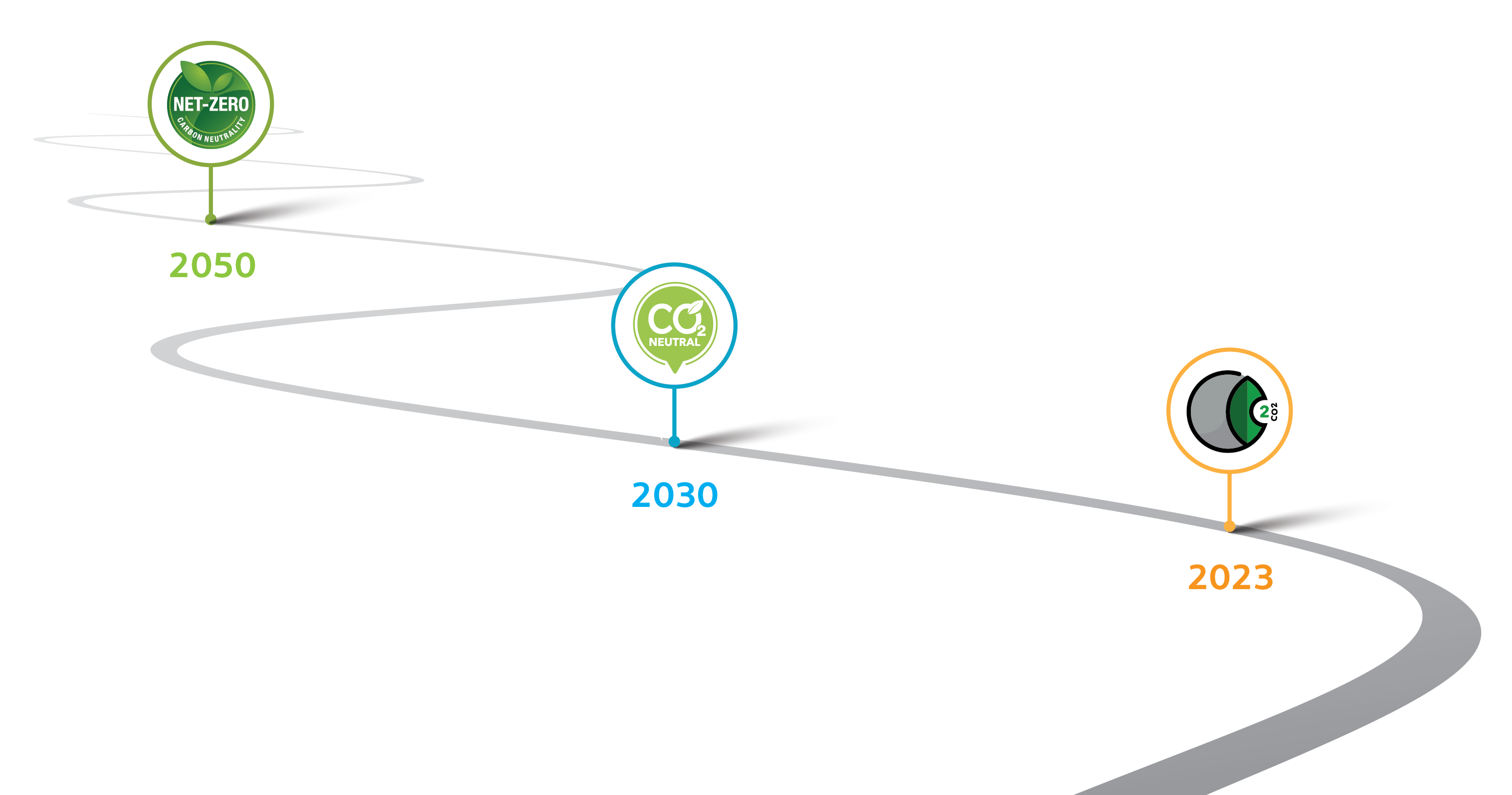

Reduce 90% emission Refrigerant in 2023

Carbon Neutrality in 2030

100% Clean energy in Electricity scope in 2030

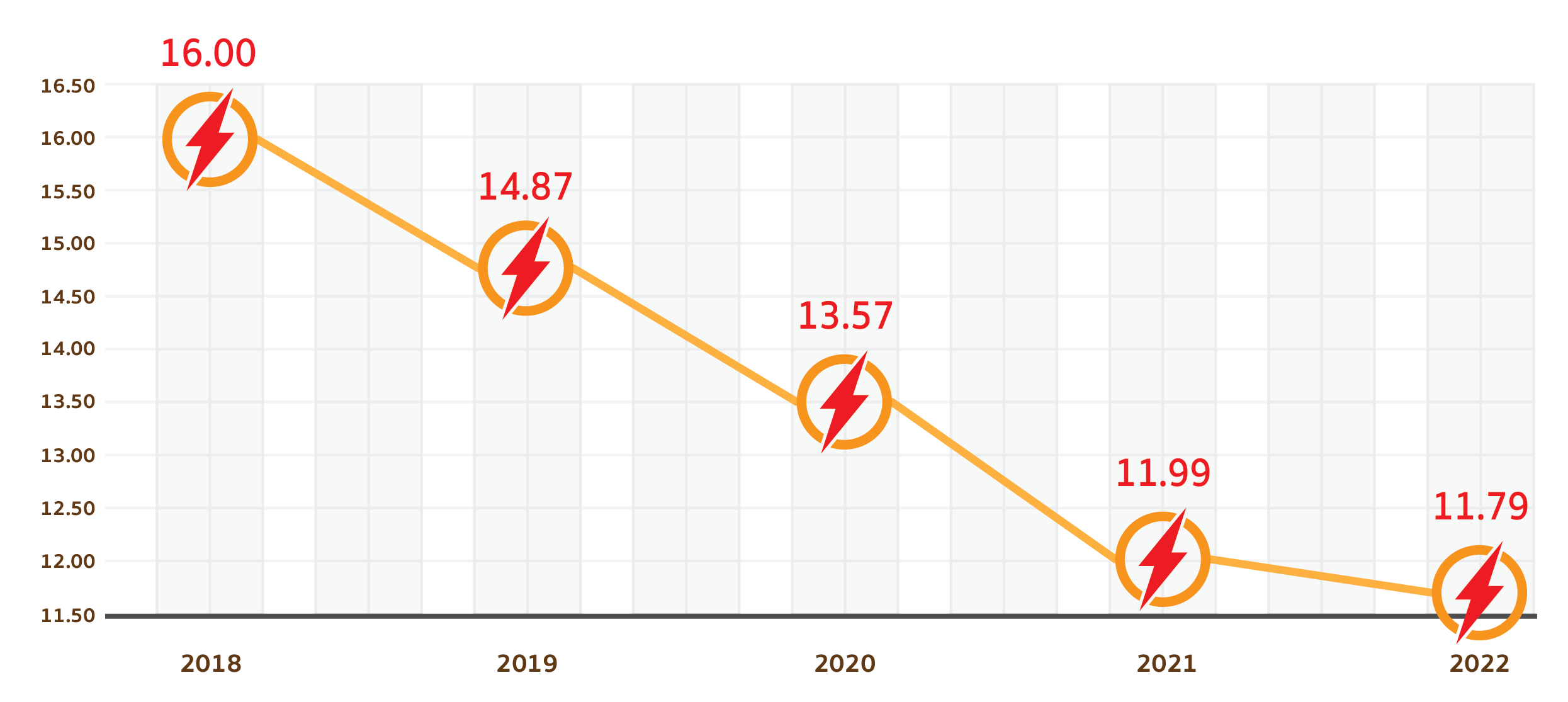

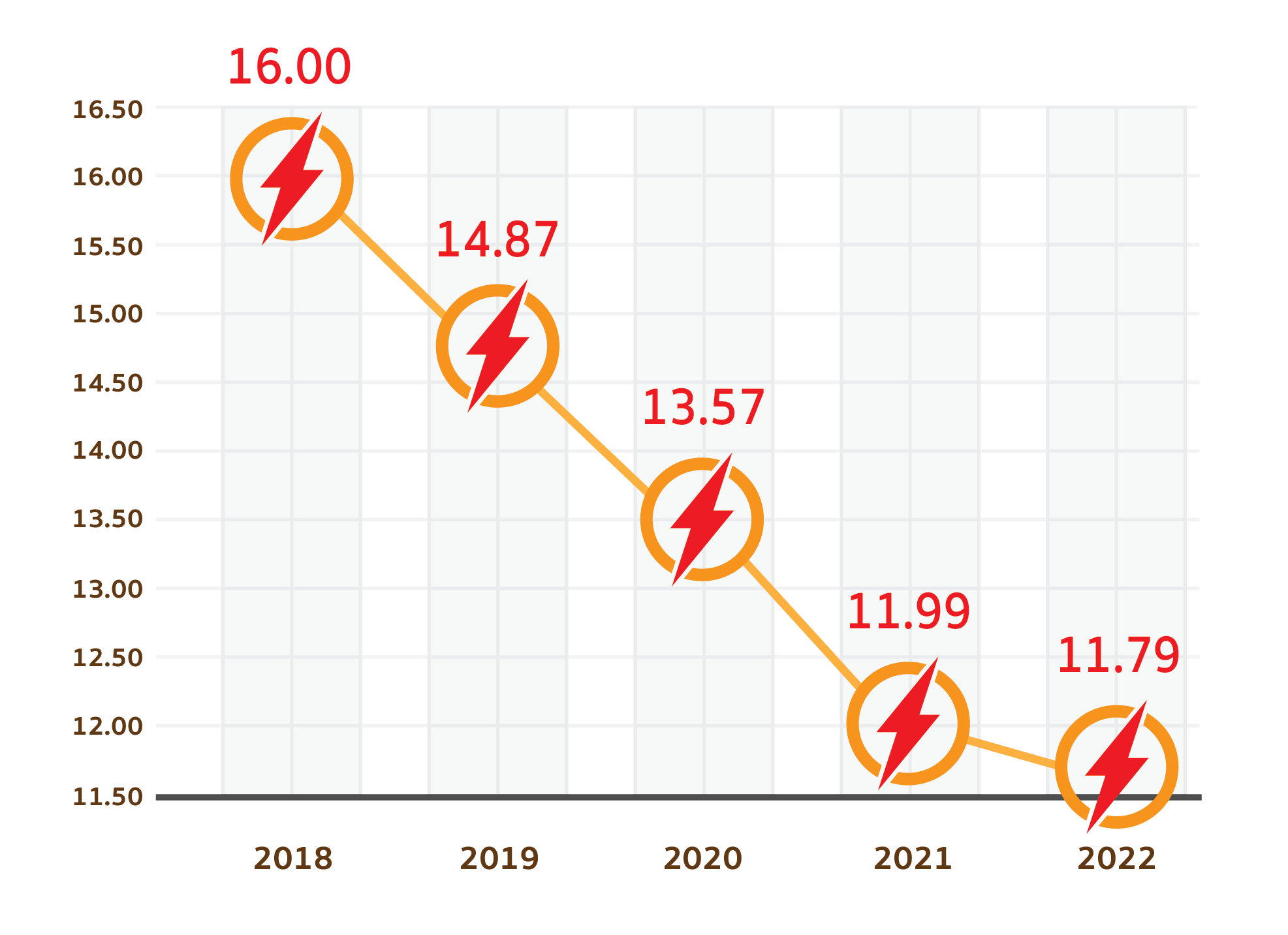

Energy consumption

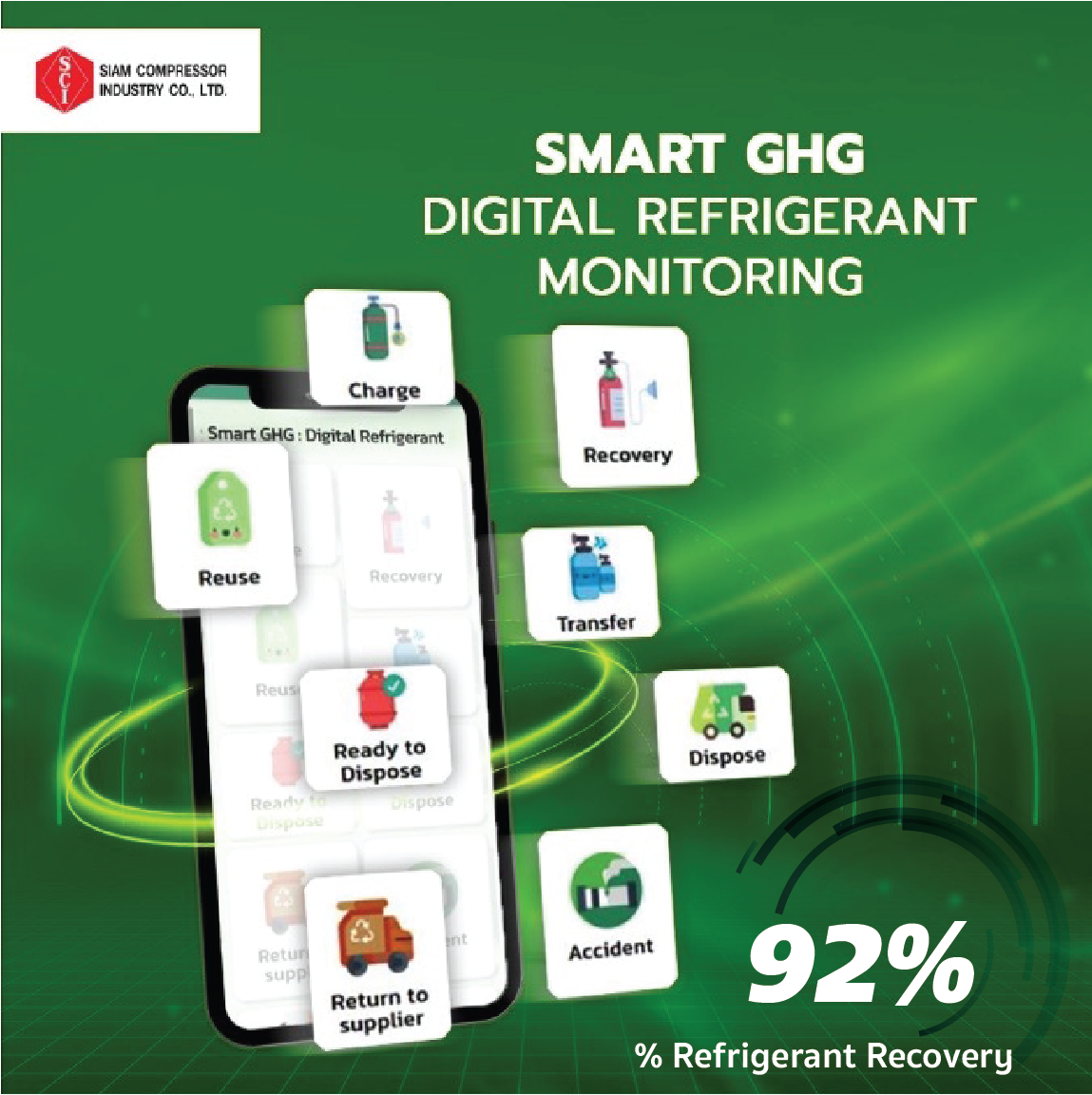

Refrigerant usage

SCI increased the proportion of renewable energy by installing a 4.5 MW solar rooftop that can produce approximately 6,000,000 units of electric energy per year, or 8% of the total energy consumption of the company.

SCI emphasizes the use of clean energy as a substitute for fossil fuels, such as utilizing electricity generated from solar energy. Shifting processes to use electricity instead of fuels, gases, and oils.

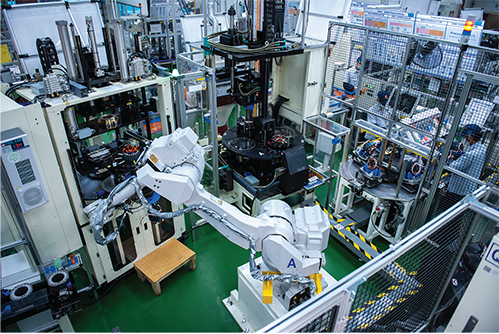

We have implemented continuous improvement activities to enhance energy efficiency. These activities can be categorized into two main types.

Energy loss reduction.

Replacing machinery with high efficiency equipment

In 2022, the electricity usage per production unit was reduced by 26% compared to the base year of 2018, resulting in energy cost savings of up to 120 million baht compared to 2018.

SCI has utilized technology by developing the Smart GHG: Digital Refrigerant application to enhance the management of refrigerants for improved efficiency. Testing operators are able to record the weight of refrigerants at every stage, including charging, recovery, disposal, and logging of leakage incidents. The application also enables real-time calculation and display of greenhouse gas emissions on a dashboard, allowing continuous monitoring and prompt identification of refrigerant leakage issues. This helps increase the efficiency of refrigerant recovery and proper disposal by 92% and reduce greenhouse gas emissions by over 70% compared to the year 2021.

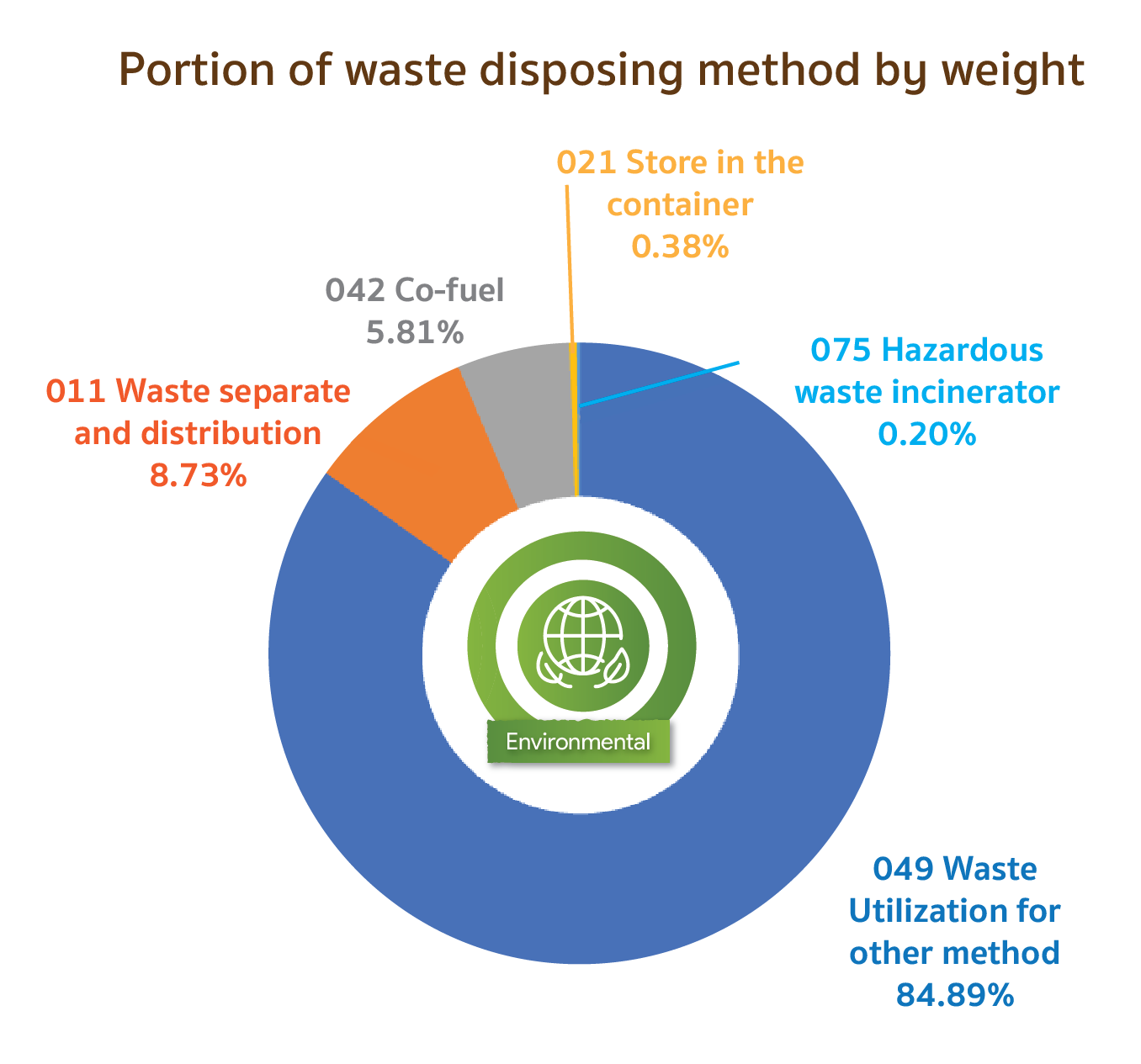

Starting with the establishment of the Circular Economy Committee, SCI has provided training by external experts to educate the management team and the Circular Economy Committee about the principles and application of the circular economy. With all stakeholders collaboration, the company is able to separate recyclable waste that can be reused or used for fuel blending, accounting for approximately 97.81%